25/03/2021

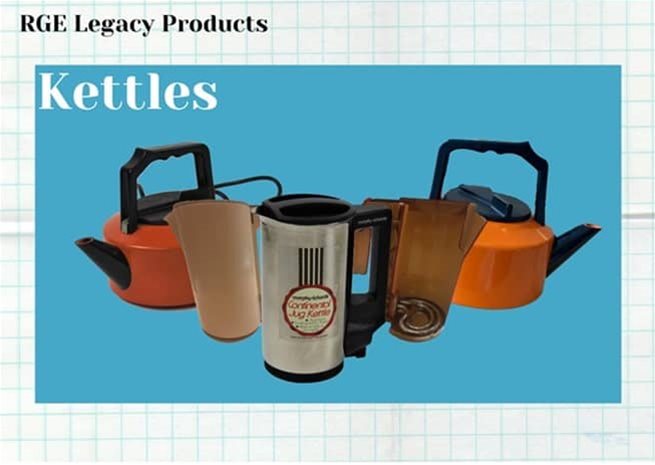

RGE Legacy Products - Kettles

In 1974, RGE began production on one of the

first plastic kettles on the market. Contracted by Redring in Peterborough, RGE made all the

tooling and components needed to produce the kettle in our tool room in Godmanchester, producing thousands of units over the next two years. Redring was a large customer of RGE’s, and had previously contracted the production of emersion heater covers, electric showers, and other heating and hot water products. The striking orange kettles were made out of glass filled Noryl. This was difficult to mould without glass fibres and flowlines showing on the surface, which meant that each kettle had to be

hand polished to ensure perfection. The kettle retailed for around £30 due to the expensive materials used and the amount of labour required to hand finish each unit.

In order to reduce production costs and keep up with industry changes, RGE went on to produce the first jug kettle in 1977. RGE engineered the kettle, a forerunner for most kettles produced today, which featured a distinctive 6 degree lean. The

tooling was also produced by RGE, and after the first impression tool was laid down, a second impression was needed to cope with demand. During the peak years of production, over one million units were made as the kettle became a market leader. The kettle initially featured automatic steam cut off, and several other features were added during the production run.

As technology advanced, upgrades were made to the kettle. New tooling was made by RGE to accommodate for the addition of sight glass to the side of the kettle to view the water level, and again as a cordless kettle with a base was added to the range. The kettle was

extremely popular, and retailed for around £21. A smaller jug kettle was also produced called the Mini Boil, which was frequently used in hotel rooms – with many still around today. Whilst working with British Domestic Appliances, RGE also produced parts of the Morphy Richards Continental Jug Kettle, making the plastic lid, handle and base to be attached to the metal body.

The production of these kettles marked a change in the production capabilities of RGE. Previously, RGE only ran a day shift, but following the huge volume of units required, a night shift was also needed as production levels increased to meet the demand. Over the 8-10 years that these kettles were produced, RGE took on more work than ever manufacturing all the

tooling in our tool room, and

moulding all parts.