01/12/2022

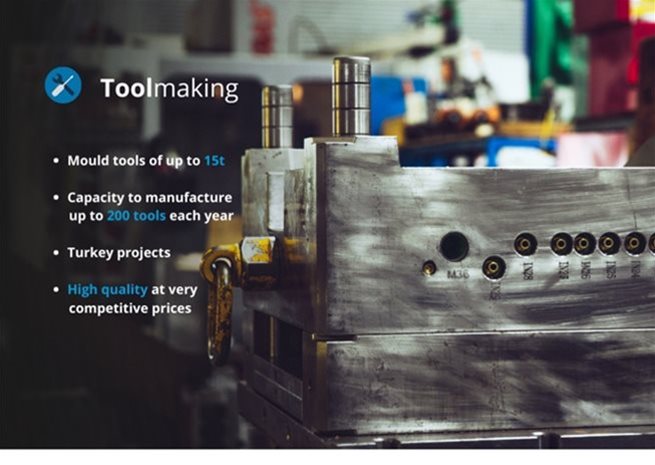

Our Services: Toolmaking

Since our start in 1965,

tool making has been at the heart of what we do. Partnering with customers from a variety of different industries, we complete more than 200

injection mould tooling projects each year, providing turnkey tool and mould making solutions across numerous sectors.

Our vast industry knowledge and experience means we are able to manufacture injection mould tooling with multiple cavities, gas injection, fast cycling, bi-injection, and over-moulding moulds. We use the latest technology to utilise the best of both the surface and solids systems of CAD modelling. We also have our own toolroom located at the

RGE Whittlesey site, giving us the ability to service mould tools and run production under the same roof.

The toolmaking process

Our engineering team works closely with our

design engineers to ensure that all of our high quality tools are tried, tested, and made to your exact requirements every time. Prototypes are made to test the functionality of each design and allow us to work on the tooling requirements for the project. Working with RGE toolmakers at our facility in China, tool designs are generated and sent back to us to validate before work begins.

A number of different tests are carried out on the tools before the manufacturing process begins. Test mouldings are made to allow us to check that the tool works correctly, and to test the mould flow in practice. This can sometimes lead us to make changes to the tools, or changes to the design of the product itself to ensure the best functionality. T1, T2, and T3 samples of the product are manufactured using the tools, and then approved by the customer ahead of production. RGE works closely with the customer, reviewing every step and each sample before production progresses. The constant reinvestments we have made to this crucial area of the business have seen our tooling capabilities expand as we take on more varied and complex projects.

We produce high quality tools at very competitive prices.

Enquire about your project with us today