28/03/2023

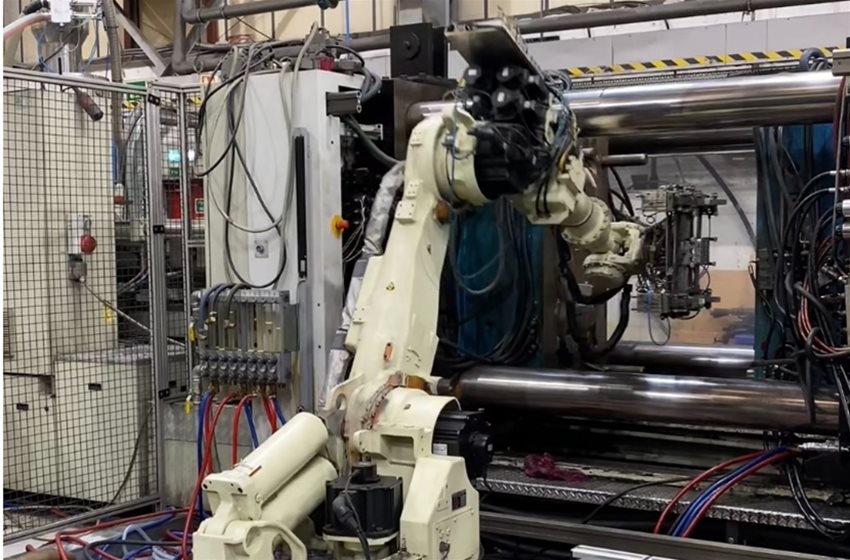

Automated Robotic Arm at RGE Whittlesey

Take a look at how we use an automated robotic arm in our Whittlesey factory:

Firstly, the automated robotic arm moves finished mouldings out of the injection moulding machine and onto a large cooling rack, as the mouldings are extremely hot when they leave the machine, and require jigging to prevent distortion and control shrinkage.

The arm then picks up cooler mouldings from the rack, and moves them over to a jig to the side for additional details and final touches to be added to the moulding.

.jpg)

Finally, the robotic arm moves the cooled mouldings back onto a conveyor belt to pass through to the working area to be packaged up and checked by hand.

Using automated robotics helps to ensure maximum efficiency within the factory, and allows our injection moulding machines to run at full capacity.

Back to News