17/06/2021

Our Design and Engineering Process

We sat down with our Design Manager Mark Temple, and Senior Design Engineer Alan Ramscar to find out more about the design and engineering processes that take our projects from an initial idea to a finished product.

The design process begins with the customer brief. Our design team is capable of creating product designs from scratch, but often build upon the customer’s initial ideas or help to adapt any previous designs that the company may have commissioned, to help to create designs that are suitable for the

injection moulding process. Sometimes this process requires our designers to make changes to an idea that has failed in the past, and bring a fresh take to the design process. Our Design Manager Mark Temple talked us through the initial meetings with clients. Mark uses this time to really listen to the client’s needs and look at any designs they may already have, in order to analyse the different parts that the product will be made up of. This initial stage is all about finding out what the client likes, before the design process begins.

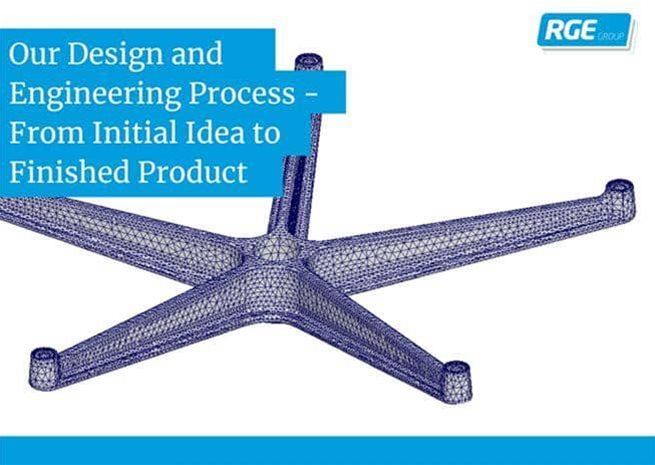

After this, Mark begins sketching and modelling, primarily using SolidWorks to produce a 3D model. He also attends meetings with the client’s in house design team or design agencies that they have previously used, and visits their facilities in order to view other products that they have produced to get a feel for their style. Mark has also been working closely with Barnaby Jones, our apprentice Design Engineer, during the design process. Once the initial designs are finished, Mark presents his ideas to the client, and adapts the designs to match their feedback. Each redesign and change is presented again to the client, until a prototype is decided on. Other tests are done virtually, for example, our chairs and chair bases undergo Finite Element Analysis to test their strength. RGE works closely with the client to ensure that they are happy with the design and that it matches their vision before prototyping begins.

A lot of our prototyping is done with a long term partner abroad, while some of the larger items are made in the UK. Prototypes are made in order to test the functionality of the design, and allow us to work out if the tooling required for the

injection moulding to produce the product is feasible. Once the prototype has been approved, we begin to decide how we want to make the

tooling that will be used to manufacture the product. Working with the RGE toolmakers in China, tools are made and sent to us to be approved. A number of different tests are carried out on the tools before the manufacturing process begins. Our Senior Design Engineer Alan Ramscar talked us through the process. Test mouldings are made to allow us to test that the tools work correctly and check the mould flow in practice. This can sometimes lead to changes to the tools to be made, or changes to the product design of the product itself to ensure the best functionality. T1, T2, and T3 samples of the products are manufactured using the tools, which are then approved by the customer before production begins. RGE maintains a close relationship with the customer, with every step and all samples being reviewed before the process progresses.

Sometimes, modifications to the tools must be made, either to remove metal, or add it on. Alan explained that this is a particularly difficult process, comprised of lots of stages. It is important that the inserts are not made too thin by removing too much metal, and care must be taken to not get too close to the ejectors and water inside the tools. Using lots of inserts as part of a tool makes it a lot easier to modify, as they can be changed without having to alter the whole tool. The initial tooling tests are performed to avoid the need for any modifications, and it is important to try and get the tool right the first time as this can be quite an expensive process.

Once the client and RGE are both happy with the samples being made, production can begin. Our factories operate 24 hours a day, 7 days a week, producing over 100,000 injection moulded parts per week – it isn’t long until the finished product is ready!

Our recently released

XO chair base is a great example of our skilled team’s design capabilities. Designed by Mark, the XO base strays from the usual U section structure with ribs typically seen on chair bases. Instead, the XO features a T section with no ribs, something that is technically and stylistically new and helps the XO to stand out against other chair bases. FEA analysis was performed on the base to test its strength and identify the stresses, under which the XO stood up extremely well. Following further testing, a prototype of the XO was made, and discussions about the width, height, and detailing of the base were had before it was approved internally. Prototypes were also sent to some of our long term clients, in order to take customer feedback on board. The tools were then made by our partners in China, which were easier to produce as the XO does not have ribs which make the tooling process more complex. The XO then went into production, and was successfully launched as the latest addition to our large selection of chair bases.

To find out more about our design capabilities, please get in touch with

sales@rgegroup.com.